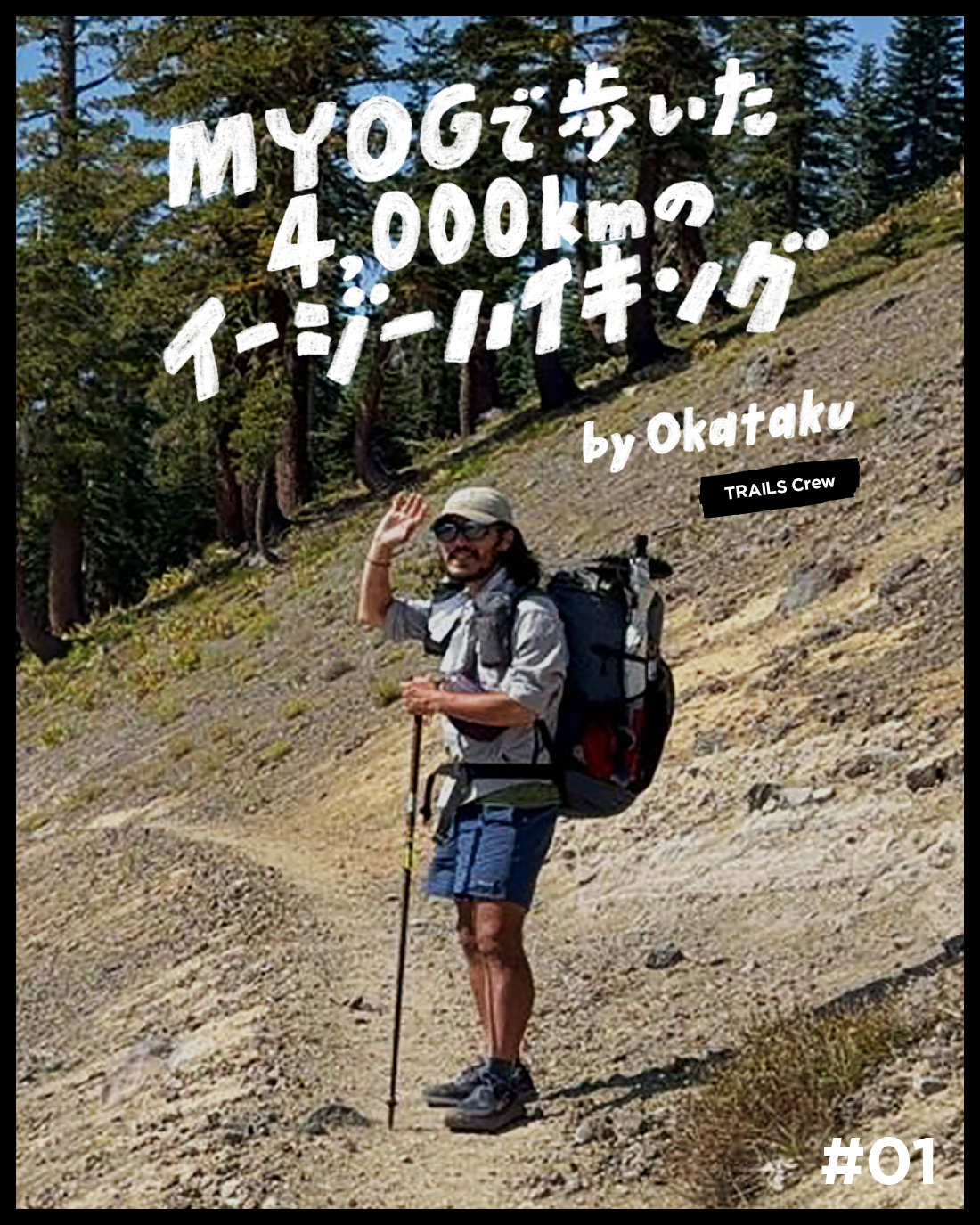

take less. do more. 〜 ウルトラライトとMAKE YOUR OWN GEAR by グレン・ヴァン・ペスキ | #07 カーボン製ULトレッキングポールの汎用化をすすめた「ライトトレック (LT)・ポール」。

Design of the Lightrek Poles

We stumbled out of the Beartooths, having braved snowstorms and crossing frigid rivers. This was an early BackpackingLight trip in 2004, and of the three pairs of early Lightrek poles that started the trip, only a single pole remained unbroken and intact. There are times when you can lighten things up too much…

When I first started lightening my pack weight, trekking poles were commonly aluminum. Leki of course seemed to be the market leader, they were everywhere. The aluminum poles didn’t seem heavy, but when I got everything else lighter, they started to seem heavier than they needed to be.

This was early internet days, so it was complicated sourcing materials. I thought carbon fiber would make a lighter pole, and I found some guy in the UK who would sell me long pieces of carbon fiber shafts with a 10mm outside diameter. This fit perfectly into a Leki tip. I made fixed length poles, because I didn’t have to figure out a locking mechanism, and they would be the lightest solution. I made the early Lightrek poles in my garage, using a hacksaw to cut the UK-sourced carbon fiber shafts to length. The pair of 130 cm poles that I had taken on that Beartooths trip weighed only 4.5 oz (128 g) for the pair.

The handles were tricky, but somehow I found a guy in Oklahoma, of all places, that would sell me boxes of handles. They were black handles used for fishing poles. So I would cut the shafts to length, and use epoxy to glue on the handle, and a dab of epoxy to hold on a Leki tip. I didn’t have any way to add nice wrist straps to the poles, but that was okay with me. Instead, I would epoxy into the base of the handle a small loop of cord, so the user could attach a thin wrist strap to it. This way when you took a picture, you could just let go of the handle and the pole would hang around your wrist until you were done with the camera. I started shipping Lightrek poles in April 2004.

The fixed length poles were a little unwieldy for traveling, so for a very brief time, we produced a two-piece version, the LT2. These were still a fixed length, so not adjustable, but they were two pieces that could be taken apart, and tightened through the use of a small rubber bushing. These used a thinner diameter shaft, and my 130 cm. pair weighed 6.5 oz. (184 g).

Around 2006 pole production transferred to Austin, TX, along with the rest of the Gossamer Gear daily operations. We founds some nice tan and grey handles from China that had a nice look and feel. When we opened the first box of 500, we noticed that to meet our specifications, they had finished the handles individually by hand. They were not identical. So the first task was to go through the box and put pairs together of similar-looking handles.

We were selling more poles, and procuring the tips was becoming an issue. We bought the tips retail from the local REI and outfitters, 4 or 5 at a time, and then searched out sources online. Eventually Leki started asking questions, and we had to source our own tips and snow baskets from China.

About this time, an ultralight backpacker from San Diego called to see if he could get some handles from us. Our president, Grant Sible, said sure, and asked him what he was doing with them. It turns out that Kevin worked at Aldila, a major manufacturer of carbon fiber golf club shafts. Kevin was experimenting with different shaft designs for making his own trekking poles. He sent us some samples, and they were lighter and stronger than what we were getting at the time, having been designed and manufactured on state-of-the-art equipment.

By 2007 Aldila was making shafts for us. These became the LT3 poles. They were still fixed length, and we would generally cut them when someone ordered a pair. Eventually we started to make them ahead of time and stock the common sizes, 115 cm, 120 cm, and 125 cm. Production was a laborious process, since the existing handles had to be bored out to fit the new shaft diameter. Kevin continued to innovate the shaft design, adding a spiral wrap in the tip section to add strength and flexibility without weight gain. Later, the wrap was added to the inside of the pole, leaving the outside smooth. The design changed some, but these poles were still light, my 130 cm pair was 4.8 oz (136 g).

In 2008 we launched the LT4 poles. These were two-piece adjustable poles, that took some time to develop. My dad, Chris Van Peski, made some of the early prototype aluminum inserts on his lathe. We found the right diameter rubber bushing but had to remove a flange on one side of every unit. Once we had a design, they were manufactured for us by Russ at Trail Designs, one example of many where early cottage gear manufacturers helped each other out. Assembly was still an ordeal. The shaft had to be trimmed, cleaned, the rubber bushing finished, the aluminum locking insert epoxied in, and the shaft had to be held upright while the epoxy set, which meant creating a special rack. We would set aside a couple of days, and make 100 at a time. With the additional length and locking mechanism, the weight was around 8 oz. (227 g) per pair.

Along the way, there were a couple of minor variations. We did a single run of camo shafts just for a different look. We also experimented with adding an insert into the top of the pole that would allow users to mount their camera to a handle for support. I even have a 3-piece pole with shock cords that weighs 3.5 oz.

Things were rolling along, but Aldila got sold, and it became clear that the new owners were not interested in making trekking pole shafts for a tiny backpacking gear company. They said they would do one last order, so we ordered as many as we dared, and set to work to find another manufacturer.

We worked with a Korean company that we met at Outdoor Retailer to produce poles to our specifications, and these became the LT5 poles available today on our website.

- « 前へ

- 2 / 2

- 次へ »

TAGS:

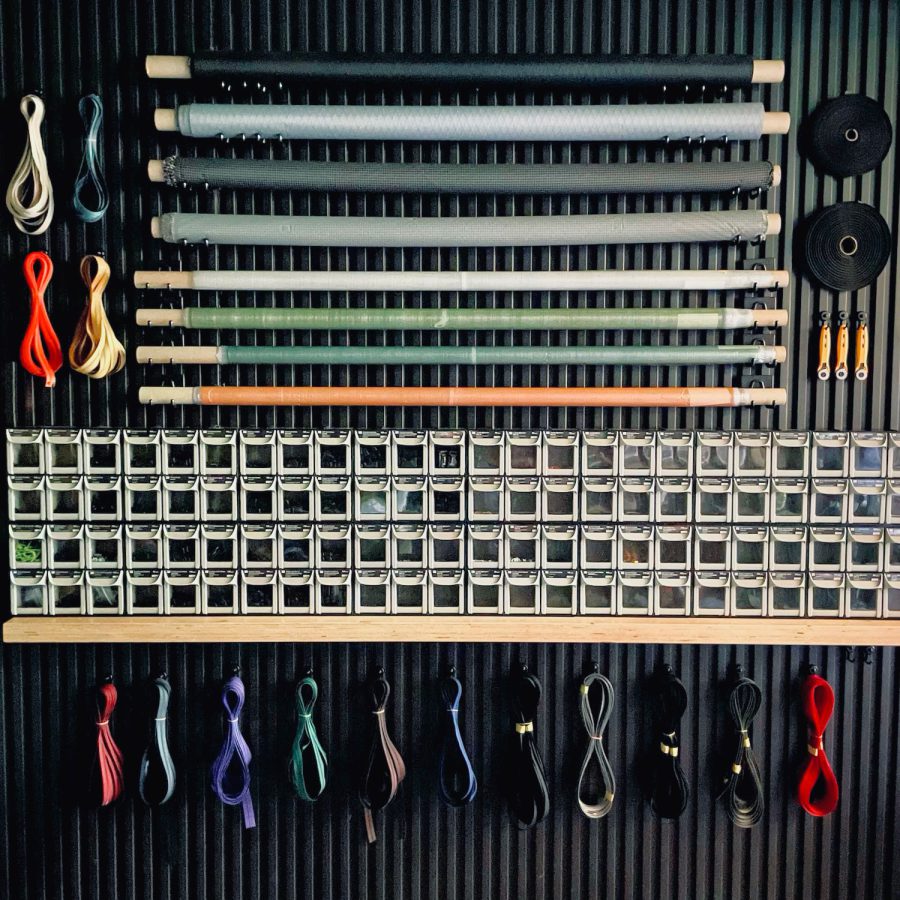

ULギアを自作するための生地、プラパーツ、ジッパー…

ULギアを自作するための生地、プラパーツ、ジッパー…  Tenkara USA | RHODO (ロード)

Tenkara USA | RHODO (ロード)  Tenkara USA | YAMA (ヤマ)

Tenkara USA | YAMA (ヤマ)  Tenkara USA | Rod Cases (…

Tenkara USA | Rod Cases (…  Tenkara USA | tenkara kit…

Tenkara USA | tenkara kit…  Tenkara USA | Forceps & …

Tenkara USA | Forceps & …  Tenkara USA | The Keeper …

Tenkara USA | The Keeper …  Tenkara USA | 12 Tenkara …

Tenkara USA | 12 Tenkara …  Tenkara USA | Tenkara Lev…

Tenkara USA | Tenkara Lev…